Products

RIVERT AND RIVERT SMART

Absolute encoders deliver high precision angle measurements.

- General

- Techspecs

- Gallery

- Documents

RIVERT AND RIVERT SMART - ABSOLUTE ENCODERS

Optimal water supply regulation without additional gear or linkage – the RIVERT and RIVERT smart absolute encoders deliver high precision angle measurements.

For almost 40 years, Rittmeyer has been developing absolute encoders that provide reliable measurements even in harsh environments. The absolute position is available immediately after power-on. Their comprehensive backwards compatibility ensures maximum investment protection: Even nearly 40-year-old predecessor devices can be migrated to the newest generation easily. Depending on the type, the encoders differ in the number of inputs and outputs and available communication interfaces.

PRIMARY APPLICATIONS

- Determine the sliding gate position of radial, tainter, crest, weir, slide, roller, sluice, lock gates etc.

- Determine the valve position of flap valves, ball valves, shut-off valves, etc.

- Monitor the orientation of sliding gates

- Determine slewing crane positions, drawbridge angles, etc.

APPLICATIONS

- Hydropower plants

- Water supply

- Irrigation

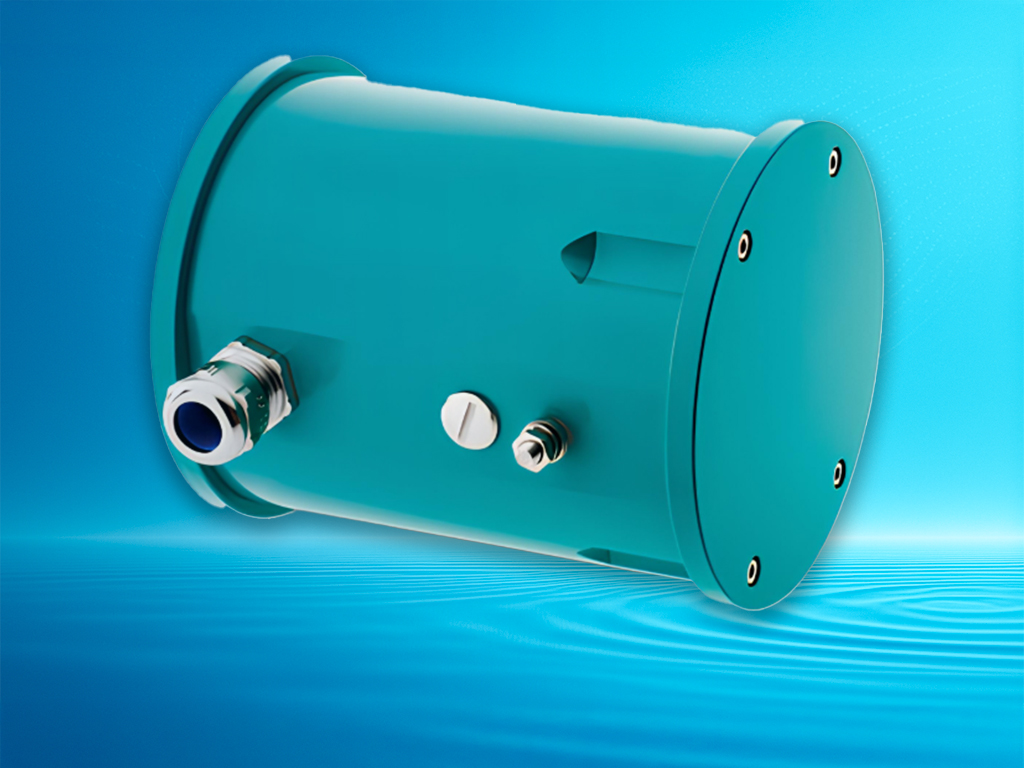

RIVERT

| Measuring range | 0 ... 360° |

| Accuracy | ± 0.044° |

| Integrated process value calculations | Limit values, linearization |

| Cable connection | With cable glands |

| Analog output | 1 pc, HART® (fully implemented) |

| Digital outputs | 4 pcs (optional) |

| Status output | 1 pc |

| Parallel code outputs | (BCD, Gray, binary) on up to 22 digital outputs (optional) |

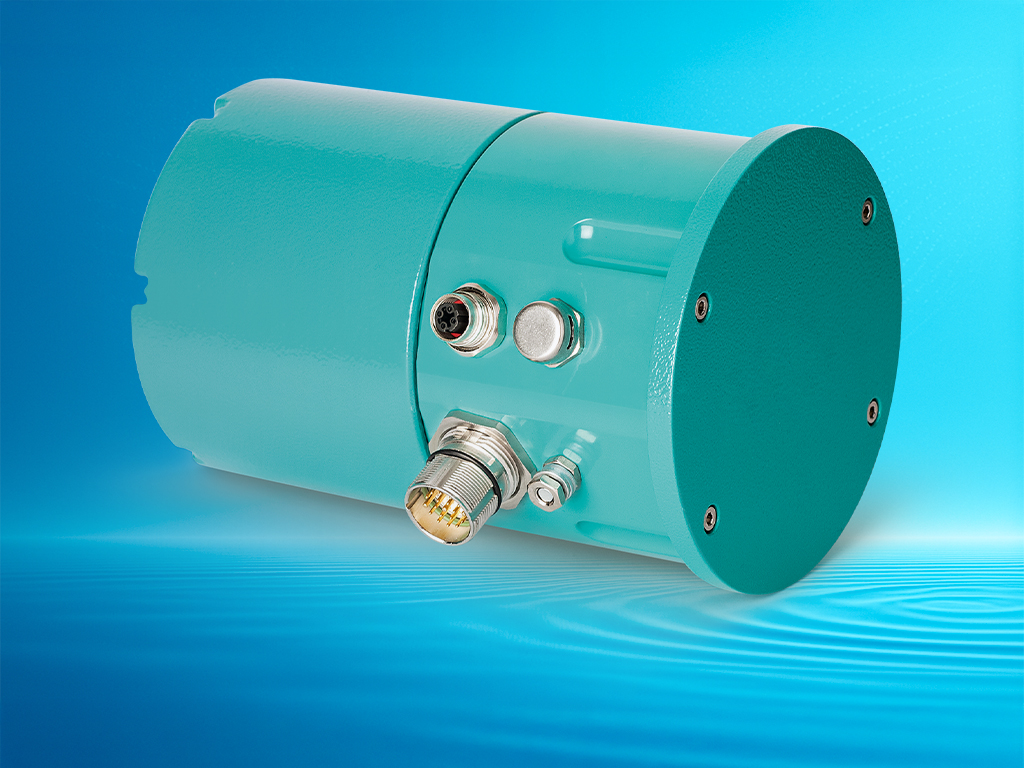

RIVERT SMART

| Measuring range | 0 ... 360° |

| Accuracy | ± 0.044° |

| Integrated web server | For easy configuration and diagnostics |

| Integrated data logger | Remotely accessible |

| Comprehensive process value processing | Rake operation, interpolation curves, integration |

| Cable connection | With plugs (M23, M12) |

| Analog output | 1 pc |

| Digital outputs | 4 pcs |

| Status output | 1 pc |

| Modbus RTU interface | 1 pc (master + slave) |

| Modbus TCP interface | 1 pc (master + slave) |

| Ethernet-100BaseT interface | 1 pc |

| Protocol | IEC-60870-5-104 |

| Support | Several sensors connected via Modbus RTU+TCP |

| Heater | Optional |